Mica Powder for Electrodes

Price 40 INR/ Ton

MOQ : 10 Tons

Mica Powder for Electrodes Specification

- Chemical Composition

- KAl(AlSiO)(OH,F)

- Surface Finish

- Simply coat the surface in paint and before it dries, add mica.

- Density

- 2.7 and 3.2 Gram per cubic centimeter(g/cm3)

- Hardness (%)

- 80 - 105.

- Water Absorption

- low water absorption properties

- Product Type

- Minerals

- Types of Refractories

- Other

- Shape

- Powder

- Porosity

- -

- Dimensional Stability

- Other

- Strength

- kgf/cm2 2200 - 2700

- Specific Gravity

- 2.5 -2.8

- Thermal Conductivity

- low thermal conductivity

- Color

- off-white or khaki color

Mica Powder for Electrodes Trade Information

- Minimum Order Quantity

- 10 Tons

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Tons Per Week

- Delivery Time

- Days

- Sample Policy

- Free samples are available

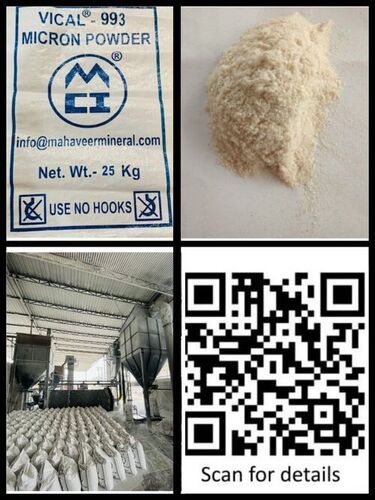

- Packaging Details

- 25kg - 50kg

- Main Domestic Market

- All India

About Mica Powder for Electrodes

Mica Powder provided by us shows great resistance against chemicals and ultra violet light. It is used for creating a sparkling effect to epoxy resin, soap, candles, etc. This powder is processed using optimum grade virgin compounds and advanced technologies already installed in our well-equipped laboratory. We provide the entire range in safe packaging. Moreover, our customers can get this Mica Powder from us at reasonable price.

Superior Performance for Electrodes

Our mica powder stands out for use in electrode manufacturing, thanks to its impressive hardness, strength, and controlled density. These characteristics promote reliable conductivity and long-lasting durability in electrode systems. The low water absorption and thermal conductivity further enhance its suitability for environments requiring stability and resistance to heat and moisture.

Versatile Application and Easy Handling

This mica powder is simple to incorporate into various electrode production processes. It can be coated onto surfaces using paint, allowing for flexible application and a smooth finish. Its powder form ensures ease of mixing or direct application, contributing to efficient workflows within industrial settings.

FAQs of Mica Powder for Electrodes:

Q: How is mica powder used in electrode manufacturing?

A: Mica powder is often integrated into electrode production as a filler or coating due to its stable chemical structure and insulating properties. Simply apply the powder with paint to the electrode surface before it dries to enhance performance and surface finish.Q: What are the benefits of using mica powder with low water absorption in electrodes?

A: Low water absorption ensures that the electrodes remain stable and resist degradation due to moisture, making them ideal for applications in humid or challenging environments.Q: When should manufacturers choose mica powder over other additives for electrodes?

A: Manufacturers should opt for mica powder when they require excellent thermal insulation, strong mechanical properties, and resistance to moisture for their electrodes, especially in high-stress or high-temperature settings.Q: Where is this mica powder sourced and supplied from?

A: This mica powder is sourced, exported, manufactured, and supplied by leading industrial specialists in India, ensuring reliable quality and consistency for global customers.Q: What is the typical process for applying mica powder to electrode surfaces?

A: The usual method involves coating the electrode surface with paint and, before it dries, sprinkling or mixing the mica powder into the wet layer to achieve optimal adhesion and finish.Q: How does the chemical composition of mica powder benefit electrode performance?

A: The chemical composition, mainly KAl2(AlSi3O10)(OH)2, provides exceptional stability, hardness, and resistance to heat and chemical reactions, improving electrode lifecycle and efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Mica Flake And Powder Category

Mica LCM for Oil drilling

Price 4500 INR / Ton

Minimum Order Quantity : 10 Tons

Shape : Other, Micron powder

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free